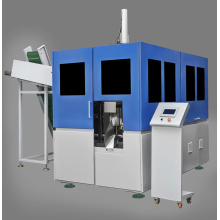

Mini plastic balls water tank blow moulding machine

| Packaging: | PE film, Wooden box, Wooden/Steel |

|---|---|

| Brand: | TONGDA |

| Place of Origin: | Jiangsu, China (Mainland) |

Basic Info

Model No.: TDB-50A

Product Description

Mini plastic balls water tank Blow Moulding Machine

It is suitable for producing plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, pesticide bottle oil bottle cosmetics, wide-mouth bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar,drum ,Tool kit , plastic model etc.

Main Features

1) Simple structure in linear type ,easy in installation .

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

1> The machine will be tested and checked at our workshop before delivery.

2>After one year, we will supply accessories are provided only one the cost price.

3>Free production technology and process configuration.

4>Installation: Experts’ team to buyer’s country after confirmation that the goods arrived in site and civil works completed get ready for installation. Funds for trip need to be payed by client and extra salary $60/day during the engineer’s journey.

5>Warranty: One year from the date of Installation or acceptance of the Plant whichever comes first

6>We will reply you within 24 hours

Suzhou Tongda Mould Co., LTD is located in zhangjiagang city TangQiao economic development zone and the traffic is developed.

The company fusion technology, Western Europe professional design and production, sales three categories and 23 kinds of series and one hundred and eighteen kinds of specifications and types of automatic bottle blowing machines, blow molding blow molding machines and the company is in jiangsu province beverage, plastic machinery enterprise one of the export base.

The company product widely sales Britain, Australia, Brazil and 55 countries and the area, deeply trusted by customers domestic and abroad.

|  |  |  |

| 2-18L blow Molding Machine | 18L-2000L blow molding machine | PET Blow Molding Machine | injection blow machine |

Product Categories : Blow Moulding Machine

Premium Related Products