6500bph 4cavity high speed Mineral water blowing machine

| Brand: | Faygo Plast blowing machine |

|---|---|

| Place of Origin: | China (Mainland) |

Basic Info

Model No.: FG-4 blowing machine

Product Description

6500bph 4cavity high speed Mineral water blowing machine Introduction:

FG series full-automatic pet bottle blowing machine is the most stable two-step automatic stretch Blow Moulding Machine

FG series full-automatic pet bottle blowing machine is the most stable two-step automatic stretch blow moulding machine.It has four cavities and the maximum capacity of the products is 2L.The capacity can be 6800-7200BPH,It can blow bottles in shapes:carbonated,mineral,pesticide, cosmetics,wide-mouth,hot filling,and other packing containers,which is made of plastic of crystalline type,such as PET etc.

1)High Automatization

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

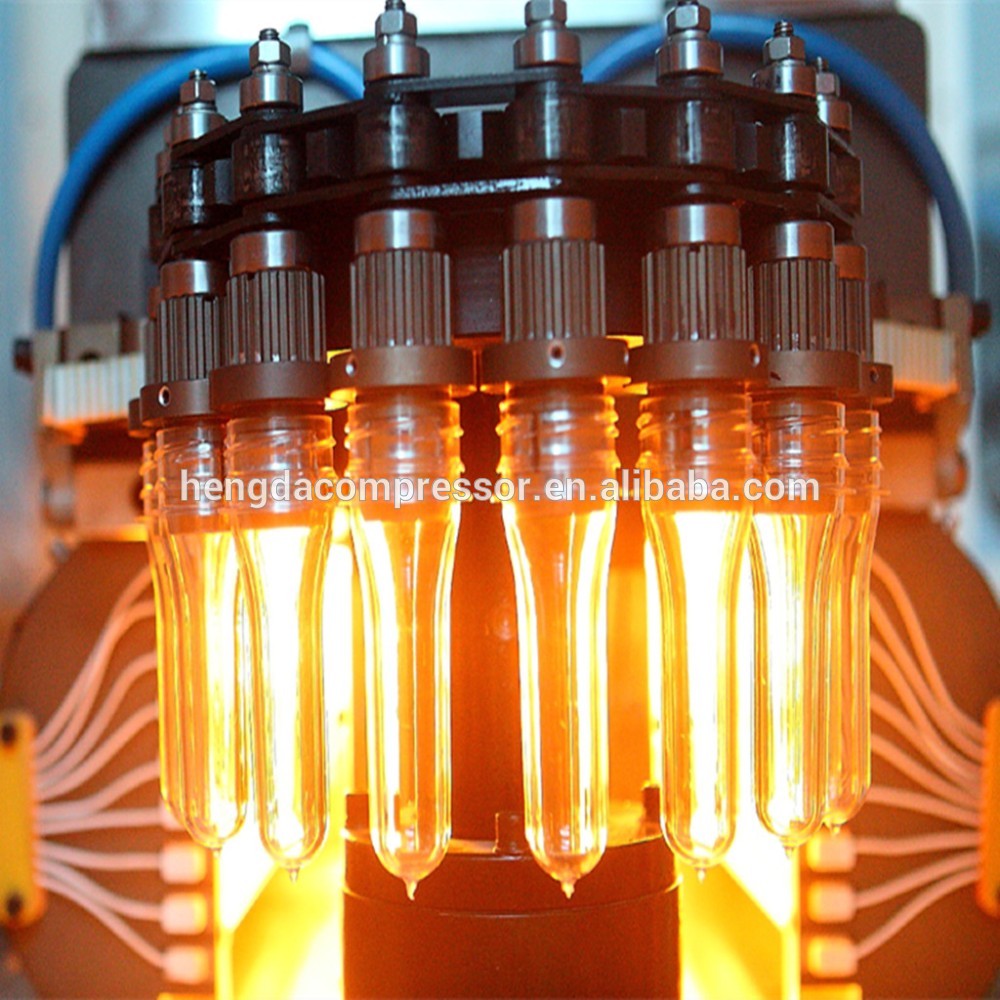

3).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

4).High Speed:6800BPH(4-cavity)

5).No Contamination:Closed production zone,good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity,air and water.

7).High Transparency:Easy maintenance,absolute safely,visual inspection,low noise.

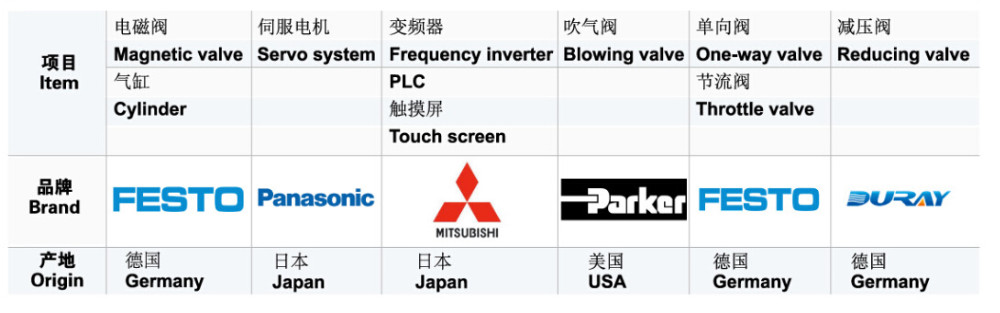

pet bottle blowing machine Settings:

a).PLC colour display:OMRON(JAPAN)

b).Pneumatic parts:FESTO(GERMANY)

c).Controller of preform transfer:Servo motor National(JAPAN)

d).Other electric parts are all world-famous brand

pet bottle blowing machine Technology is below:

Model | FG4 |

Cavity number | 4 |

Blowing capacity | 6800BPH (500ml) |

Applicable preform | Neck:20-25mm |

Height:105mm | |

Applicable bottle | Neck: 20-25mm |

Volume: Max2000ml | |

Height: Max328mm | |

Diameter: Max105mm | |

Electricity consumption | Installation power:51kw |

Heating oven power:46kw | |

Heating oven operating power:26kw | |

Voltage:380V/50Hz | |

Air consumption | Pressure:30bar |

Capacity:3.5m3 | |

Mold water consumption | Pressure:4-6bar |

Temperature:6-13℃ | |

Flow:45L/min | |

Oven water consumption | Pressure:4-6bar |

Temperature:6-13℃ | |

Flow:26L/min | |

Machine Dimension | L3900*W900*H2500mm |

Machine weight | 3500kg |

Configuration of pet bottle blowing machine

1.Minimize distance of heating heats

Heater distance in the heating oven is reduced to 38mm, compared with the conventional heating oven, it saves more than 30% electricity consumption.

2.Modularized design conception

Adopting modularized design concept, to make it convenient and cost-saving for the maintenance and changing spare parts

3.Efficient and soft perform inlet system

By rotary and soft preform inlet system, the speed of preform feeding is ensured meanwhile, the preform neck is well protected.

4.Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

5.Our Patents:

FG series high speed and energy saving type blowing machine have 8 utility patents and 5 invention patents

6.Mould:

Product Categories : PET Blow Molding Machine

Premium Related Products