Electric professional plastic pet water bottle neck cutter for sale

| Brand: | Faygo |

|---|---|

| Place of Origin: | China (Mainland) |

Basic Info

Model No.: FG-C

Product Description

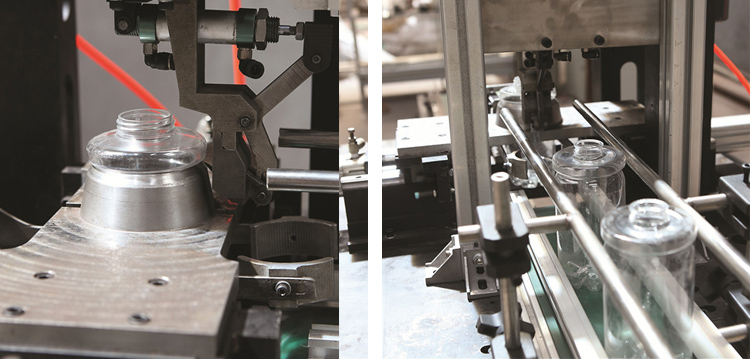

Electric professional plastic pet water bottle neck cutter for sale

For PET cans, plastic cans, PP cans of incision.

Multi function cutting machine, stable performance. Can adjust the speed and knife holder. Cut the size of the bottle edge to reach the best requirements. Under high efficiency, the finished product is round and smooth with no lace at the same time.

The utility model has the advantages of good trimming quality, high safety performance, simple and compact structure, convenient operation and maintenance, small volume, light weight, low noise, small quantity of fittings, and size and caliber. The machine is easy to operate! The cutting edge is smooth and without burrs.

Products pictures

Plastic bottle neck cutter advantages

1. Production line features:High output,economic labor and good quality.

2. The design is rational, structure is compact and operation is easy.

3. Manner of adjustable: frequency conversion controller.

4. Character: low noises. Save electricity30%

5. Extrude systemType: it adopts three section gradual change screw with rhombus shape, which contribute to the good plasticizing effect.

6. Lift Framework:adjusting the gap between mould inlet and the mould can minimize the remains of the products.

7. The automatic level is very high so save the salary and expenses.

8. Multifunction incision machine;Stable performance.You can adjust the speed and knife rest to make the bottle size cutting out meet the best sealing requirements.The product incision under high efficiency is smooth,neat and no laciness.

| Model | FGC-1 | FGC-2 | FGC-3 | FGC-4 | FGC-5 |

| Cutting speed(BPH) | 1000-1200 | 2000-2400 | 3000-3600 | 4000-4800 | 5000-6000 |

| Cutting platform height | 1000mm(100mm/±100mm adjustable) | ||||

| Cutting motor | Delta servo motor | ||||

| Conveyor length | 2000mm*2 groups | ||||

| Cutting container diameter | 70-300mm | ||||

| Low pressure air capacity | 0.1m³/min 8 bar | ||||

| Air Cylinder | Airtac | ||||

| Conveyor Motor | 120W*z, delta speed motor | ||||

| Control system | Mitsubishi PLC control system | ||||

| Total | 0.5KW | ||||

| Dimension | 5000*1700*600mm | ||||

| Weight | 450kg | ||||

FAYGO UNION GROUP has 3 branch factories. One is FAYGOBLOW which design and make Blow Molding Machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET Blow Molding Machine is one of fastest and most energy-efficient design in the world. Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line. Third factory is FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO RECYCLING can make up to 4000kg/hr. PET bottle washing line, and 2000kg/hr plastic film washing line.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

Product Categories : Plastic Bottle Cutting Machine

Premium Related Products