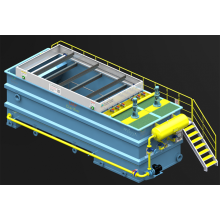

3 phase oil immersed transformer 750kva

Basic Info

Model No.: S11

Click on the follow link to find out more information: https://www.newelectricpower.com/oil-type-distribution-transformer/

Company Info

- Company Name: Henan New Electric Power Co.,Ltd.

- Representative: Gao zhaolong

- Product/Service: Oil Immersed Transformer , Dry Type Transformer , Isolation Transformer , Auto Transformer , Control Transformer , Distribution Transformer

- Capital (Million US $): 10,000RMB

- Year Established: 2017

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 51% - 60%

- Total Annual Purchase Volume (Million US $): US$5 Million - US$10 Million

- No. of Production Lines: Above 20

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Luoyang Xigong District

- Contact Person: Mr. Tony Gu

Premium Related Products

Other Products

Hot Products

Automatic plastic pet bottle neck cutting machinePP / PE high output pvc oca film laminating machineFaygo PVC pipe extrusion machineConical Twin Screw ExtruderHigh quality good price pet bottle recycling plantPVC granulation line by fan to bettyFG40 injection blow machine by fan to betty zhangportable air compressor for sale fusheng screw compressor compact cng compressor for home use (2m3/h to 5m3/h)Biogas Compressor and Enrichment System 11KW Biogas CompressorCM-A1-2L 800-1200PCS/H used plastic injection blow molding machinesRefrigerated air dryer for compressor system25Kw BC1000 booster air compressorhigh pressure piston air compressor for PET blowingHigh pressure 300 psi Piston Air Compressors (single unit)YDERC-60SA/W shaft coulpling driver screw air compressorOne step good price auto 5 gallon 20 liter pc hdpe abs plastic water bottle automatic extrusion blow molding /moulding machine